Lifting Beyond Limits: The Future of Vacuum Lifter Technology

The world of lifting and handling equipment has experienced a revolution in the last decade. As companies continue to embrace automation, there has been an increasing demand for safer, more efficient, and reliable machinery. Vacuum lifters have emerged as an ideal solution for various material handling applications, including manufacturing, warehousing, and construction. This article explores the future of vacuum lifter technology and how it is transforming the lifting industry.

Contents

ToggleWhat are Vacuum Lifters?

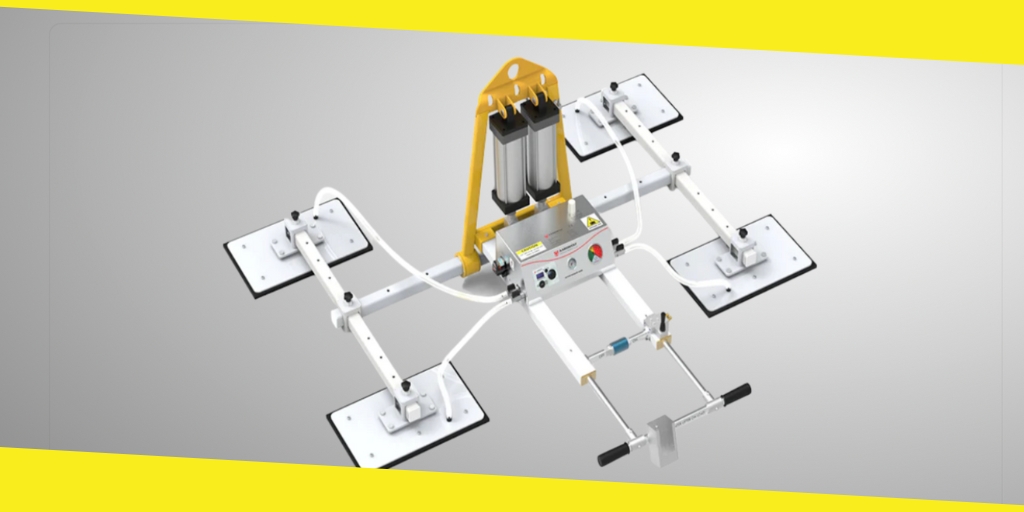

Vacuum lifters are devices that use vacuum technology to lift and move loads. They operate by creating a vacuum seal between the lifting surface and the load to be lifted. This vacuum seal creates a suction force that holds the load in place. Once the load is secured, the vacuum lifter can move it to a different location. Vacuum lifters come in different shapes and sizes, depending on the application. They can be designed to handle a wide range of loads, from small boxes to heavy metal sheets.

Vacuum lifters are widely used in various industries, including glass manufacturing, construction, and logistics. They are ideal for lifting loads that are too heavy, too fragile, or too awkward to be lifted by human workers. Vacuum lifters have become increasingly popular in recent years due to their safety, efficiency, and versatility. They offer a safer alternative to manual lifting, reducing the risk of injuries and accidents in the workplace.

Advancements in Vacuum Lifter Technology

Vacuum lifters have been around for decades, but recent advancements in technology have made them more efficient, reliable, and versatile. New materials, such as lightweight aluminum and composites, have made vacuum lifters lighter and easier to handle. New vacuum pumps and sensors have made them more efficient and precise, reducing energy consumption and improving performance.

One of the most significant advancements in vacuum lifter technology is the integration of automation and artificial intelligence (AI). With the use of sensors, cameras, and algorithms, vacuum lifters can now identify and select the best gripping points on loads automatically. They can adjust their suction force and lifting speed based on the weight and shape of the load. They can also detect any anomalies or defects in the load, such as cracks or deformities, and adjust their grip accordingly.

Automated vacuum lifters offer many benefits over traditional manual lifters. They are faster, more accurate, and require less human intervention. They can work around the clock, increasing productivity and efficiency. They can also reduce the risk of accidents and injuries in the workplace, as they eliminate the need for human workers to lift heavy loads manually.

Future Trends in Vacuum Lifter Technology

As technology continues to evolve, so will vacuum lifter technology. Here are some of the emerging trends that are likely to shape the future of vacuum lifters:

-

Collaborative Robots

Collaborative robots, also known as cobots, are robots designed to work alongside human workers. They are equipped with sensors and AI algorithms that allow them to interact with their human counterparts safely. Collaborative vacuum lifters can offer many benefits in the workplace. They can take over the lifting tasks that are too heavy or too dangerous for human workers, reducing the risk of injuries and accidents. They can also work in tandem with human workers, improving productivity and efficiency.

-

Wireless Communication

Wireless communication is becoming increasingly prevalent in the lifting industry. Vacuum lifters can now be equipped with wireless sensors that transmit data in real-time to a central control system. This system can monitor the lifter’s performance, including suction force, lifting speed, and energy consumption. It can also alert the operator to any anomalies or defects in the load, ensuring the safe and efficient handling of materials.

-

3D Printing

3D printing, also known as additive manufacturing, is a process of creating 3D objects layer by layer using digital designs. 3D printing has many potential applications in the lifting industry, including the production of customized vacuum lifters. With 3D printing, it is possible to create vacuum lifters that are tailored to specific loads, shapes, and sizes. This can lead to increased efficiency and productivity in the workplace, as well as reduced costs and waste.

-

Smart Sensors

Smart sensors are sensors that are equipped with AI algorithms that allow them to detect and analyze data in real-time. Smart sensors can be used in vacuum lifters to monitor the lifter’s performance, including suction force, lifting speed, and energy consumption. They can also detect any anomalies or defects in the load, such as cracks or deformities, and adjust the grip accordingly. Smart sensors can improve the efficiency and reliability of vacuum lifters, reducing the risk of accidents and increasing productivity.

-

Cloud Computing

Cloud computing is becoming increasingly popular in the lifting industry. Vacuum lifters can be equipped with sensors that transmit data to the cloud in real-time. This data can be analyzed and used to optimize the lifter’s performance, including suction force, lifting speed, and energy consumption. Cloud computing can also be used to store and analyze data from multiple vacuum lifters, allowing operators to monitor and manage them remotely.

Conclusion

Vacuum lifter technology has come a long way in recent years. From simple manual lifters to fully automated systems, vacuum lifters have become an essential tool in many industries. As technology continues to evolve, we can expect to see more advancements in vacuum lifter technology. Collaborative robots, wireless communication, 3D printing, smart sensors, and cloud computing are just a few of the emerging trends that are likely to shape the future of vacuum lifters. These advancements will lead to safer, more efficient, and more reliable lifting solutions for companies around the world. If you are looking for this advanced technology and solution, then Tait Sales is the right place for you! Click here to know more visit Tait Sales & Consulting.

Recommended For You

8 Common Traits Of People Having WhatsApp Addiction

Most Inside

Most Inside offers high-quality recommendations and valuable updates to enhance all aspects of your life, providing premium guidance and enriching experiences.